T: +86 18823794757

E: sales01@davecl.com

E: sales01@davecl.com

ADD: Room 504, President Commercial Centre, 608 Nathan Road, Mongkok, Kowloon, HK

Views: 0 Author: Site Editor Publish Time: 2024-01-12 Origin: Site

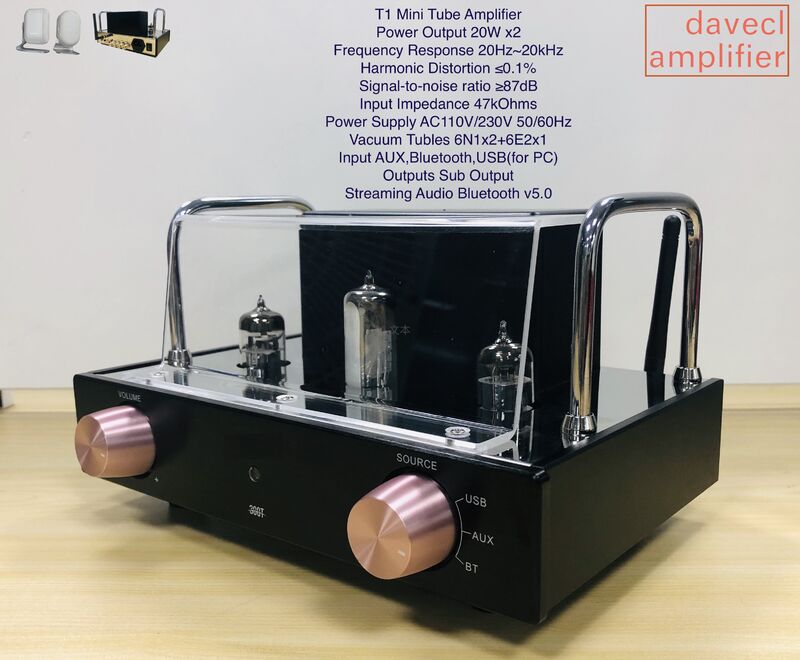

Simply share some knowledge about tube amplifiers

Tube amplifiers operate at high voltage and low current. The screen voltage of the final power amplifier tube can reach 400-500V or even thousands of volts, while the current flowing through the tube is only tens to hundreds of milliamperes. The input dynamic range is large and the conversion rate is fast.

Most tube amplifiers use discrete components, manual wiring, and welding, which are low-efficiency and high-cost. This is particularly evident in developed countries.

The open-loop performance of the tube power amplifier is better than that of the transistor. It does not need to add deep negative feedback and can work stably without adding a phase compensation capacitor, so its dynamic performance is better.

But in addition, the life of the electronic tube is relatively low, and some technical indicators drop significantly after one or two thousand hours of use. Tube amplifiers consume high power and often work in Class A status, which further reduces efficiency. However, there are basically no factors harmful to sound quality such as transient intermodulation distortion, switching distortion, and crossover distortion.

Tube amplifiers have no advantages over transistor amplifiers in terms of weight, efficiency, lifespan, and power consumption, and their disadvantages are all obvious.

Generally speaking, the sound quality of the tube amplifier is soft and pleasant. To be more specific, the low-frequency sound of the tube amplifier is soft and clear, and the high-frequency sound is delicate and clean. Expressing the human voice is its strong point.

In use, the electronic tube must have good ventilation and heat dissipation. Overheating will inevitably shorten the life of the electronic tube, so the temperature of the electronic tube should be kept as low as possible.

Electronic tubes are afraid of vibration, so it is also important to take anti-shock measures to avoid vibration as much as possible. If you do these two things, the service life of the electronic tube can be at least doubled!

For this reason, there should be appropriate space around the tube equipment, especially above it, to allow for good cross ventilation, and if possible, use fans to help dissipate heat.

When a high-voltage power supply is applied to the cathode of the electron tube before it reaches the required temperature, its cathode will be damaged and the life of the electron tube will also be shortened. Therefore, if the electronic tube equipment has a preheating device, it must be used!

For example, turn on the low-voltage power supply of the filament first to preheat, and then turn on the high-voltage power supply. If there is no preheating device, don't rush to connect the input signal. You can turn down the volume to the minimum and wait for 20 to 30 minutes to warm up the machine before using it.

If a side-heated rectifier tube is used to supply high voltage to the entire machine, it just provides a simple and effective high-voltage delay. In addition, during normal use, do not switch the power on and off frequently!

The pros and cons of active vs passive speakers.Many people like active speakers, but they may not really understand the pros and cons of passive and active speakers. They just heard that active speakers are better, which may bring a lot of trouble to their future use. It

hat exactly is "Dolby Sound"?The word "Dolby" in "Dolby Sound" is actually the surname of Dr. Dolby (formerly R.M. Dolby) in the UK. The Dolby Laboratory established by Dr. Dolby has successively invented a number of technologies such as the Dolby Noise Reduction System and the Dolby Surround Sound

Dolby Atmos speaker setup reference standardSpeakers with Dolby Atmos are designed to conduct sound upwards, creating and reproducing extremely realistic overhead sound by bouncing off the ceiling. There are two versions of speakers with Dolby Atmos:Integrated units that also include traditional for

The vinyl resurgence has moved beyond a niche hobby into a mainstream cultural phenomenon. In 2026, as more music enthusiasts and B2B hospitality clients look to integrate the warm, analog sound of vinyl into their spaces, a common technical question arises: does the turntable itself produce audible

An Active speaker utilizing Bluetooth relies on a direct, short-range point-to-point connection between the source and the speaker, while a WiFi-enabled Active speaker connects to a local network, allowing for higher bandwidth, multi-room synchronization, and greater range without interrupting audio

In the modern era of audio technology, the demand for portable, high-fidelity sound has transformed the commercial and personal audio landscapes. The shift from traditional wired systems to wireless solutions has placed the Active speaker at the forefront of consumer electronics. As of 2026, the int

When testing the sound, you can adjust the buttons slightly in the range of 20-20KHz, and constantly record the voice comparison of the volume of each node. Under the rated sound, you can debug the equalizer, different people have different habits of the sound color of the music, and you can adjust

Upgrading your av receiver can make your home entertainment better. New av receivers give you clearer sound and sharper video. They also have controls that are easier to use. You get things like 4K and 8K video, new audio formats, and smart connections.Think about this: Does your av receiver stop yo

Davecl Industrial CO., LIMITED

robinwang111

+86 18823794757

+86 18665912888 (whatApp/Wechat)

sales01@davecl.com

![]() Room 504, President Commercial Centre, 608 Nathan Road, Mongkok, Kowloon, HK

Room 504, President Commercial Centre, 608 Nathan Road, Mongkok, Kowloon, HK

![]() Floor 4, Building 2, No.1, DongFeng Xilu, Qingxi Town, Dongguan, GD, China

Floor 4, Building 2, No.1, DongFeng Xilu, Qingxi Town, Dongguan, GD, China